MODEL MSW

Special Design for

High Productivity

High Cost Performance

High Speed Net Machine

Up to 18RPM

Overview

In widest net machine in 11, 14, 18, 22mm pitch, our Model YSA with servo-motor was popularized in European countries. Due to computerized net machine, though there are many advantages, as concerned as price, it was not match in Asian countries.

Taking into consideration the customer’s demand in cost performance, we are pleased to announce that New Model MSW corresponding to the widest depth of netting was developed and is specialized for 11mm, 14mm, 18mm and 22mm pitch.

New Model MSW succeeds to the feature Model MSA. Besides, future easier maintenance and higher stability were investigated. Being a high effecient netting machine, at the same time, New Model MSW is assembled at AMITA, Japan.

Designing Concept

In designing Novel Model MSW, we made an importance in the following points:-

- Easy to Adjustment

(4 Position K/T Cams, K/T Lever, Warp Supply System, Weft Supply System and so on) - High precision parts

- High rigidity and Long durability

Details

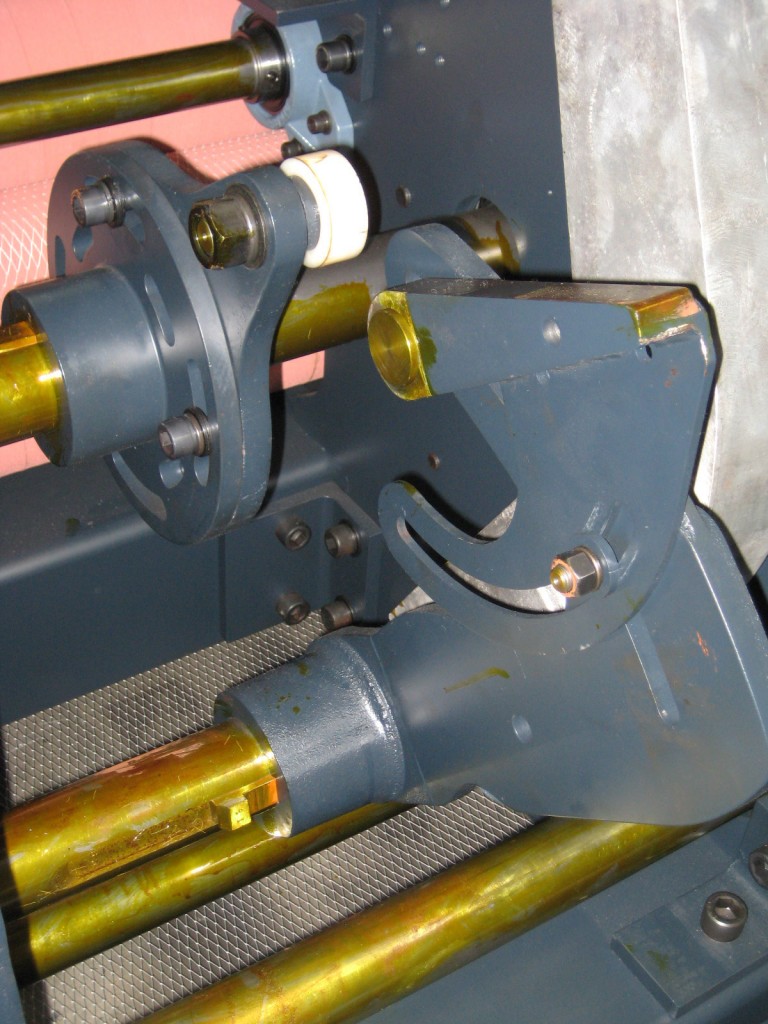

Auto Warp Supply System

When the mesh size is changed the warp supply automatically increases (or decreases) accordingly. This feature increases the net machine overall productivity while simplifying overall operation.

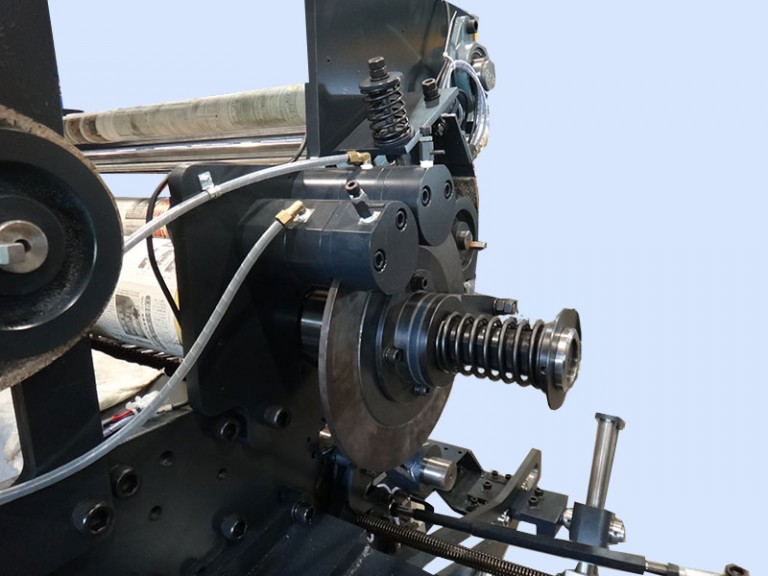

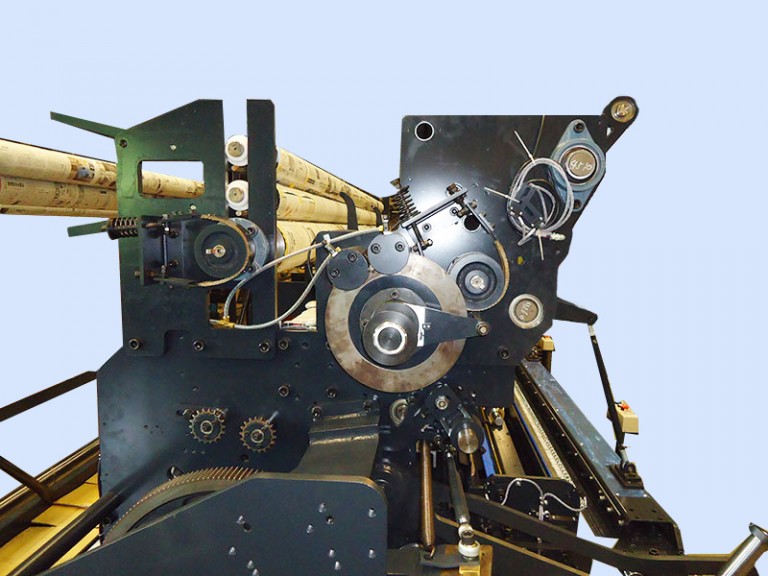

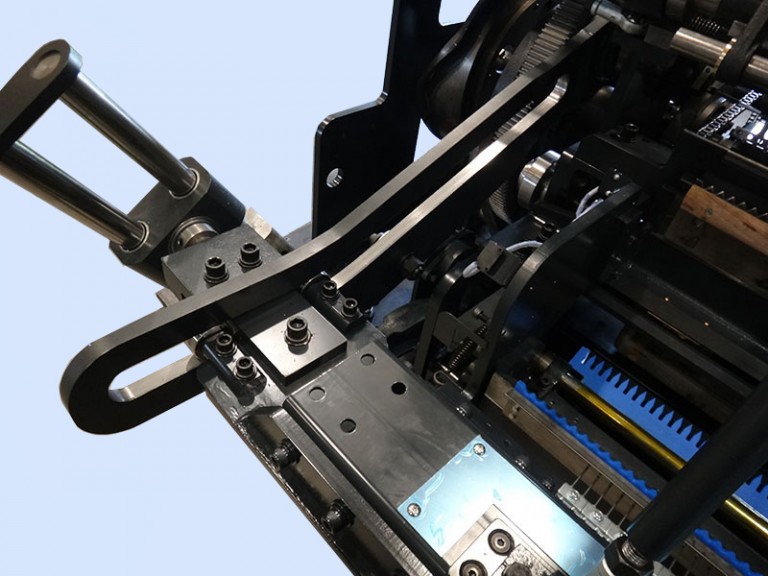

Belt Drive

The main motor drive system is changed to belt type instead of rolling chain. The belt drive is vibration free, rotates smoothly and the noise level is significantly low. Also it can reduced the shake of machine during the inching operation.

Bobbin

The center bore size of the new bobbin is made bigger than our regular bobbins. Hence the weight of the bobbin is reduced as well as the winding tension is optimized. Generally the winding tension in a bobbin gradually differs from the inner turn to outer turn. The ratio of tension difference in the new bobbin is 1:1.4 that is considerably negligible. So, the supply tension from the bobbin is almost constant from the full bobbin to empty bobbin. Thus Quality of netting have been improved extreamely.

Control Panel

The electric switches and circuits are up-to-date, modern and easy to maintain. The displays show current and total rows knit. A third readout, monitoring the net machines looming speed, is available as an option.

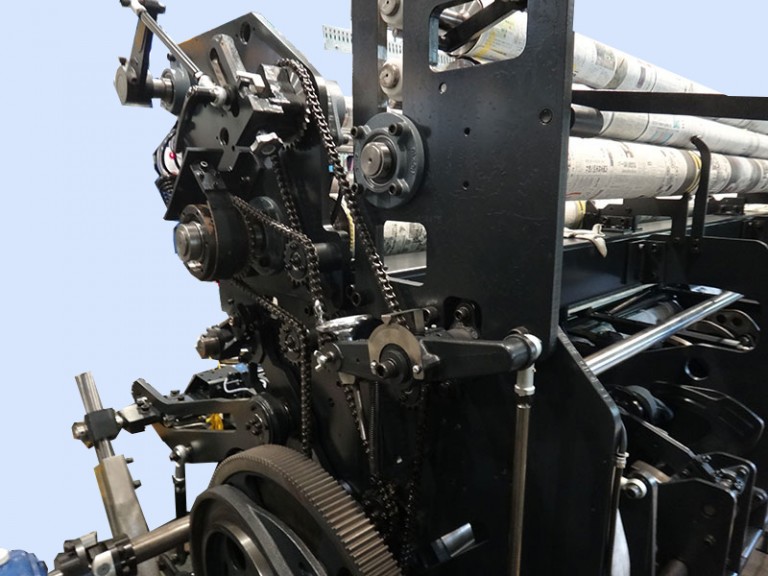

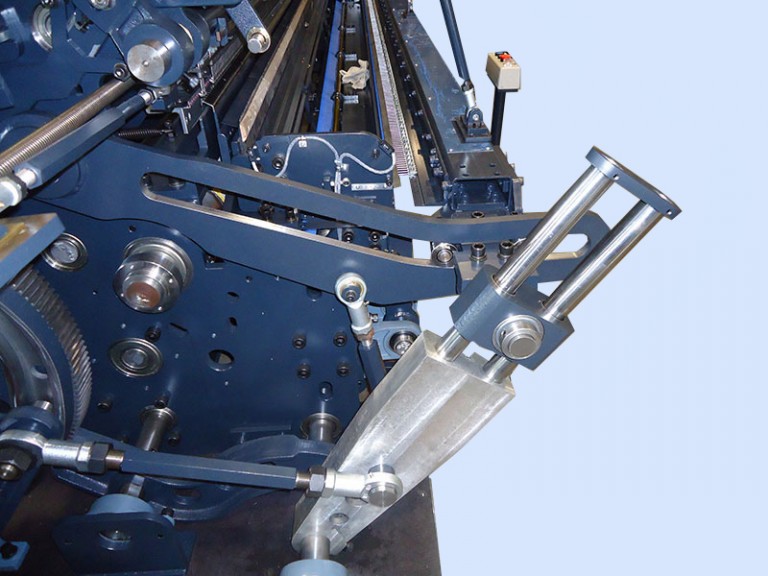

Easy Adjustment

The machine is designed to have easy access for the operators and maintenance personnel’s from all the directions. Both the side structure of the machine and the rear portion is opened and easy to access.

Easy Adjustment by Gauge Setting

- Simplified for adjustment points and figure out by numerical data for adjustment points.

- Speedy adjustment points and figure out by numerical data for adjustment points.

- Easy changing for depth and twine of net to be shortening idle time.

Even Warp Tension

The warp roller covering is upgraded to felt type roller covering. Felt type materials are soft flexible in nature. Thus they provide even twine-tension on the entire warp rollers. All the fixed twine guide pipes are now upgraded to rolling guide pipes. So, this system reduced friction between the twine and the pipes. Thus constant tension is maintained on these pipes too.

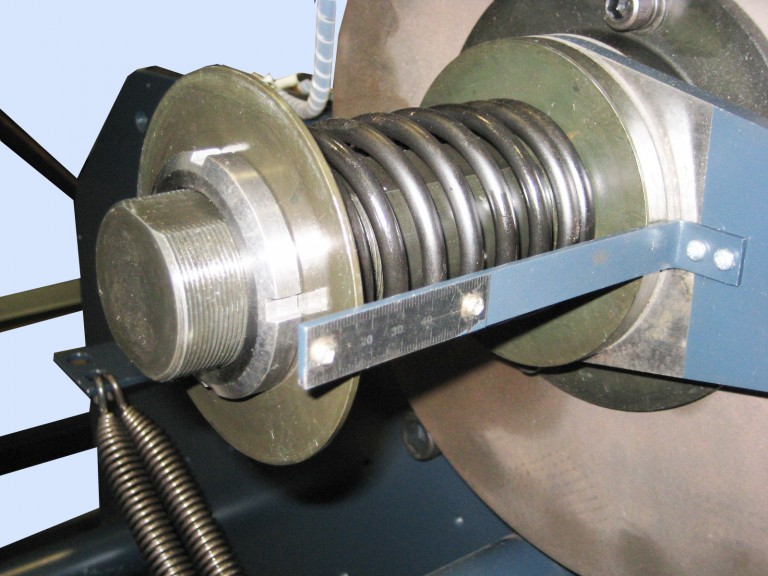

Knot Tightening Brake

Movement of the knot-tightening pipe is stabilized to start from a constant location. This improvement insures an even knot tightening regardless of changes in the weather, like humidity and temperature. The strength of knot -tightening can be adjusted by gauge movement.

Lower Hook

A special nitration treatment, more resistant than hard chrome, has been applied to the stainless steel (JIS SK) hooks to insure high durability.

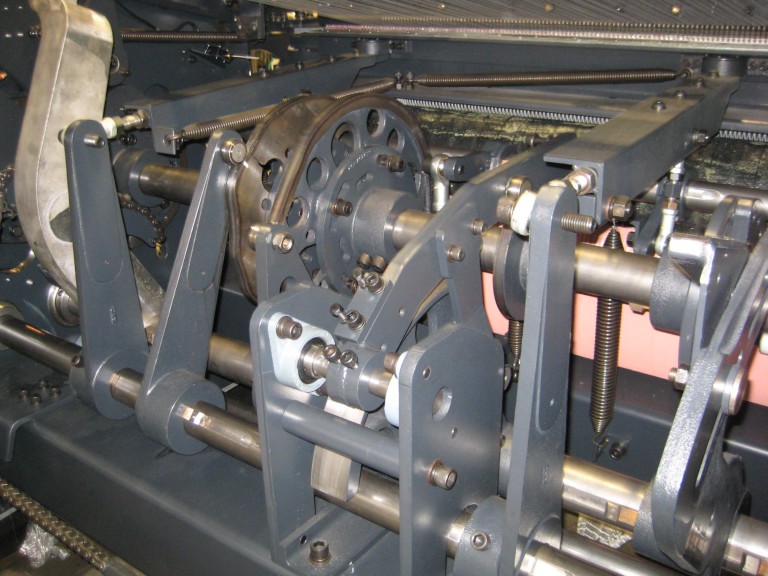

Lower Hook Frame

The lower hook frame is supported by middle supports. This system results in much less deflection of the frame, without increasing its weight, for smoother travel of the lower hooks. The life of the mechanism driving the lower hooks is prolonged.

The weight of the lower hook frame is significantly reduced leading to smoother movement and less vibration.

Lower Hook Rail

The redesigned lower hook rail is of a one-piece design and requires no adjustment. The rail is angled to facilitate the smooth release of warp twines from the lower hooks. In addition, large bearings are used to improve performance and insure consistency of the lower hook movement.

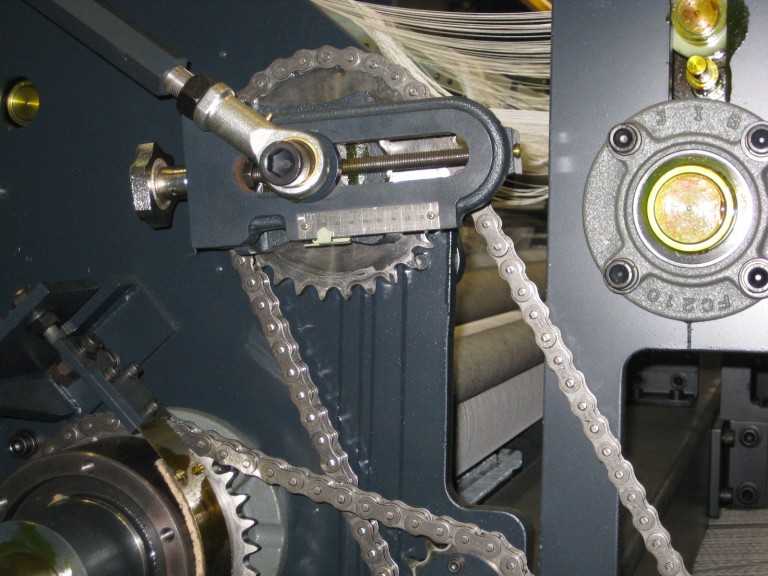

Lower Hook Stroke Rod

The lower hook stroke rod is made of a solid piece of steel (JIS SS400), instead of bolted pieces. The length of the new stroke rod is adjustable with turnbuckles. This new system results in a stronger stroke rod and accurate, yet simple, adjustment of the lower hook movement.

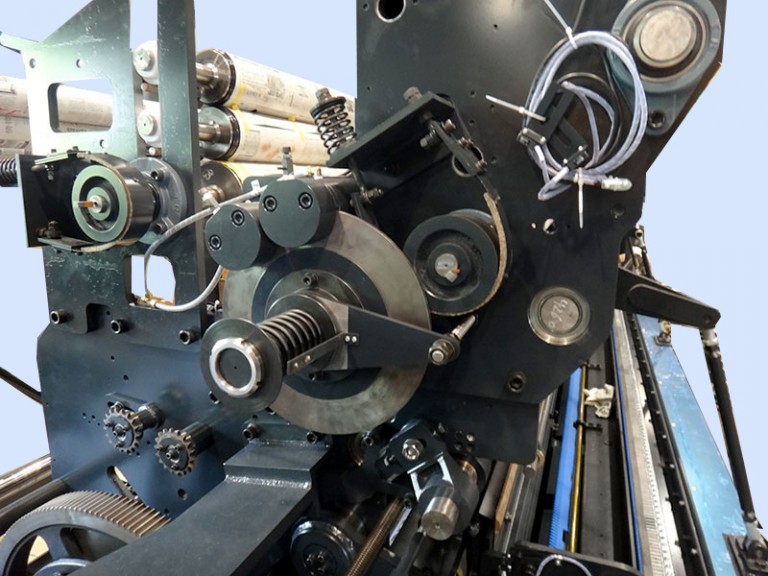

Mesh Forwarding(Gauge Movement)

Mesh forwarding supply can be easily adjusted by gauge setting, thus enhancing and simplifying operation of the net machine.

Mesh Forwardin Rollers

A third roller has been added to the repositioned mesh forwarding mechanism. The result of the new configuration is more stable and uniform movement of the netting. Thus improved quality is gained.

Safety Lock

When activated this feature makes it impossible to operate the net machine. This lessens the chance that the net machine will experience damage as a result of untimely operation, and is another feature geared towards protecting your operators from undue harm.

Shuttle

The outer shape of the new shuttle is specially designed to handle fine twines. This shape reduces friction considerably and helps the twine to pass gently under the shuttle. As a result the improved net quality and stable machine performance is obtained.

Stable Loop Making (Reed Plate)

To allow for high speed operation the reed angle has been lightened by using aluminum. Nonetheless, the reed plate is made of steel to insure long life and reliably.

Twine Separator

Redesigned so that its motion always follows a guide. The stainless steel (JIS SUS304) twine separator is quiet and accurate. In the unlikely event that the twine separator fails, it retreats to the vertical position. Thus the upper hooks are not damaged when the twine separator moves towards them.

Upper Hook

Specifically constructed to insure the most suitable shape and design, these stainless steel hooks with special nitration treatment insure long durability.

Warp Rollers

The warp rollers have been repositioned for simplified threading. The diameter of main roller has been changed from 6″ to 8″ and the composition of the rollers are 8″, 6″, 6″, 4″. Thus, proper tension is maintained along the entire length of the roller system.

Warp Tension Shutter System

Improvements were made to the warp tension springs. The system has been upgraded to a warp tension shutter system, in which are very difficult to break.

COMPANY

We continuously pursue the ideal of best technology and service, and seek to provide new value while unlocking the unlimited potential of net machine for customers.

MUSEUM

AMITA has been involved in the net making industry since 1817. Past Models are showed here.

![Belt-Drive[1]](http://www.amita.co.jp/wp-content/uploads/2015/10/Belt-Drive1.jpg)

![Bobbin-002[1]](http://www.amita.co.jp/wp-content/uploads/2015/10/Bobbin-0021-768x568.jpg)

![easy-adjustment[1]](http://www.amita.co.jp/wp-content/uploads/2015/10/easy-adjustment1-768x576.jpg)

![Gage[1]](http://www.amita.co.jp/wp-content/uploads/2015/10/Gage1.jpg)

![Even-Tension[1]](http://www.amita.co.jp/wp-content/uploads/2015/10/Even-Tension1-768x576.jpg)

![Mseh-Forward[1]](http://www.amita.co.jp/wp-content/uploads/2015/10/Mseh-Forward1.jpg)

![Switch[1]](http://www.amita.co.jp/wp-content/uploads/2015/10/Switch1.jpg)

![Bobbin-Shuttle[1]](http://www.amita.co.jp/wp-content/uploads/2015/10/Bobbin-Shuttle1-768x555.jpg)